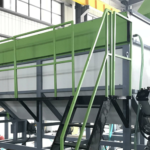

The film washing line, depending on the configuration, enables cleaning of heavily soiled, printed and oily film used in food packaging, industry, agriculture, etc. The main elements of the washing line are made of high-quality stainless steel, which significantly extends its service life. The capacities we offer are 500, 1000, 1200, 1500, 2000 kilograms per hour, higher capacities are a multiple of the previous ones. The final capacity is adjusted to the type of material and its degree of soiling.

The high degree of automation of our lines allows us to optimize the production process, save energy and minimize the necessary personnel.

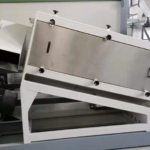

The use of a squeezer, an innovative device for drying and compacting the washed material at the end of the plastic washing line, brings significant economic benefits in the subsequent production process, e.g. about tenfold reduction of the storage space necessary to store the material after washing and no need to use an agglomerator on the extruder.

Plastic washing lines are always designed and configured in accordance with the individual requirements of the customer.