The single screw (one extruder) extrusion line for production of granules with an agglomerator is used to process clean, post-production materials.

In the standard configuration of the line, the processed material is transported to the agglomerator by a belt conveyor. An optional method of feeding film is unwinding it from a roll. The motor drive of the belt feeder and the film unwinding device are synchronized and controlled by an inverter. The speed of the conveyor belt and the film extraction are fully automatic. On the conveyor belt we can install a metal detector that will automatically stop it and signal the detection of metal objects.

If there is a need to modify the amount of input material, we equip the line with the necessary dosers: gravimetric or volumetric.

Our single screw extruder ensures proper homogenization and degassing of the material.

In the case of more damp material, we offer our customers double vacuum degassing equipped with cleaning.

One element of the machine which is particularly important are cleaning screens. An important issue at the stage of technical arrangements is to familiarize our experts with the type of material, its degree of contamination, moisture content, etc. Depending on the assessment of the input material, we can offer the customer plate screens of various diameters, piston screens and the increasingly popular self-cleaning screens.

The high quality of the materials used for the screw, cylinder and other components allows for uninterrupted operation of the machine for a very long time.

Our lines are equipped with material drying systems and, depending on the type of material, we offer a centrifugal or a vibrating screen. An additional component for drying the material is the blowing system for transporting the material to the .

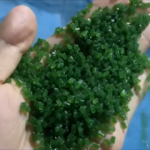

The type of the cutting head and the method of cutting are selected depending on the MFI value of the material. Our machines use a water ring, water spray or air die face cutting system.

In our machines, we use touch panels with Siemens software (SMART series). The installed GSM Wi-Fi module allows our service to connect directly to the machine and diagnose the problem on-line. In many cases, this allows the defect to be rectified without any cost and in a very short time.

The equipment of the electrical cabinet consists of elements from well-known manufacturers such as Siemens, ABB, OMRON, Schneider. This provides our customers with easy access to spare parts after the warranty period. High-class electrical components also ensure the efficient operation of machine protection systems against electrical overload.