The water treatment system for the plastics washing line is equipped with many innovative technical and design solutions. It has a compact structure and can be placed directly on water reservoirs without the need to take up additional space. It has an automated control system that allows for continuous work 24/7. However, the most important advantage of the water treatment system for the plastics washing line is self-sufficiency and the ability to work without sewage connections.

The purified water can be used continuously without the need to replace it, which is an invaluable benefit for the environment.

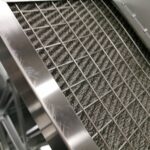

In the water treatment system, flotation agents mixed with dirty water cause the precipitation of solid contaminants. Contaminants that are lighter than water float to its surface and are removed. On the other hand, pollutants heavier than water settle at the bottom of the reservoir, from where they are cyclically drained into the sedimentation reservoir. In the centre of the reservoir there is a water collecting pipe through which the clean water is recirculated.

Separated impurities go to the reservoir and assume the form of solid waste.

Thanks to the innovative and compact design, it is possible to reduce dehydration costs by up to 10% compared to traditional solutions.